A to Z of Traffic Barrier Control Systems

What am I looking for?

A: Vehicle barriers are designed to block roadways to thwart vehicle-based attacks.

There are two main categories permanent or temporary and they function exactly as the names imply.

Permanent barriers have a below-grade steel substructure that is cemented in place, as well as above grade Model

They provide continuous protection at a single location.

Types include:

Wedge barriers get their name because of their wedge shape when viewed from the side.

They are sometimes called Plate barriers because the most common type uses a steel plate angled toward the approaching vehicle.

A barrier is actually a wedge type, though its open, see-through design and energy-absorbing band technology makes it a much more aesthetic solution.

CALL FOR A QUOTE TODAY 915-240-4747

![]()

![]()

What are the Different Types of Vehicle Barriers?

The basics of Barriers

What am I looking for?

A: Vehicle barriers are designed to block roadways to thwart vehicle-based attacks.

There are two main categories permanent or temporary and they function exactly as the names imply.

Permanent barriers have a below-grade steel substructure that is cemented in place, as well as above grade Model

They provide continuous protection at a single location.

Types include:

Wedge barriers get their name because of their wedge shape when viewed from the side.

They are sometimes called Plate barriers because the most common type uses a steel plate angled toward the approaching vehicle.

A barrier is actually a wedge type, though its open, see-through design and energy-absorbing band technology makes it a much more aesthetic solution.

![]()

Beam barriers use a beam extending across the road. Usually the beam swings vertically to allow the vehicle to pass, but horizontal swinging versions and telescoping beams are also available. Some vertical swing designs require a massive steel counterweight (many thousands of pounds) to balance the beam, and a large capacity hydraulic system to move the beam.

![]()

Model vertical pivot lift barrier uses a spring-balanced aluminum beam (with internal energy-absorbing bands) and requires only a 24-volt DC electric operator. Sometimes beam barriers will have a fence section attached to restrict pedestrian traffic. The fence can be either ornamental or a high-security, anti-climb design. We offer our model barrier with this fence option

![]()

NMSB XII revolutionizes Drop Arm Crash Beam design. The highest security crash beam available worldwide, the NMSB XII has received the DoS K12/L3 or 15,000 lbs. at 50 mph crash certification with remarkable results. The NMSB XII can be hydraulically and/or manually, counter-balance operated.

fortified, "sling-shot" concept Drop Arm barrier system design, are an ideal stopping mechanism for maximum perimeter security. After crash impact, the test vehicle was propelled backwards up to 6 ft.

The US State Department

representative on site to witness and certify the test results stated that the

test was one of the most remarkable DoS had ever witnessed. The successful test

further demonstrates WE Barrier's dedication to continued

product innovation and leadership in crash barrier engineering and quality.

WE offers other engineer rated Drop Arm Crash Beam barrier

systems. The NMSB XIIA1 Drop Arm (crash-beam) barrier is for intermediate-threat

security facilities. The NMSB XIIA1 is a choice addition for commercial

application. The NMSB XIIa1 is crash tested and engineer rated meeting DoS K4/L3

standards to stop a 15,000-pound vehicle traveling at 30 mph.

Drop Arm barrier operation overcomes terrain issues due to snowplows or other

roadway obstacles. Its optimal operation as a "sally-port" system to operate in

unison with

steel-plate or bollard barriers creates a virtually impenetrable, stoppage and

trapping configuration. The standard barrier opening lengths range from 12'-16',

16'-19', and 20'-22'. In the down and secure position the top of the barrier is

33" (83.8 cm) above the road surface. Hot-dip galvanized for years of service.

EPA approved self-contained attached housing unit. Drop Arms lower cycle / hour

operating systems are best suited for minimal vehicle-traffic, access-control

scenarios. Standard barrier deployment time is 8-15 seconds per cycle depending

on varying barrier size. Vertical or horizontal open/close options as well as

custom sizes and configurations are available.

![]()

Wedge barriers get their name because of their wedge shape when viewed from the side.

They are sometimes called plate barriers because the most common type uses a steel plate angled toward the approaching vehicle.

![]()

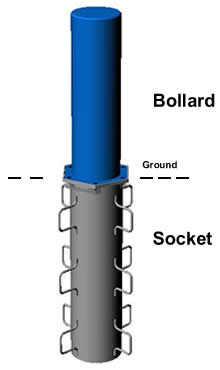

The B3 system consists of four components:

An in-ground socket into which the bollard is inserted

A family of bollards with different vehicle stopping power ratings, all of which fit into this same standard socket.

A cover plate for the socket if no bollard is installed

A trim ring to finish off the top of the socket when a bollard is in place.

Here are some of the typical ways you might use the B3 system:

Install sockets and cover plates during construction or as the first phase of a security system upgrade then add the bollards later on.

Install sockets and cover plates and keep the bollards in storage, installing them in the sockets if security conditions warrant (VIP visitor, specific threat, etc.) and removing them when the need passes.

Install sockets and low stopping power bollards (or even dummy bollards), and then replace the bollards with higher stopping power ones if security conditions change.

Install the system in those locations where you might need occasional vehicle access, and you can tolerate manual bollard removal.

Install the system in locations where aesthetics are important, and use one of over 250 colors. Or use our digital finishing process to complement your facility's architecture by making the bollards look like granite, marble, polished steel, or virtually any material. B3 bollards are good looking, aesthetic vehicle access control barriers.

Bollards are vertical cylinders. The name derives from the large cylinders used on wharves to tie down ships, and comes from an old English word for tree trunk. Retractable bollards are used to block roadways, whereas fixed bollards are widely used for perimeter security around a facility. We offer bollards in a range of stopping powers, plus we have a unique design called the B3 ("B-Cube") for which the vehicle stopping power can be upgraded without excavation and replacement.

The B3 (pronounced "B-Cube" and standing for "Basic Bollard Barrier") is a low cost, yet aesthetic perimeter security system that can be installed in phases as budget and security requirements evolve. The B3 is what is called a passive (rather than active) vehicle barrier. That is, it does not retract into the ground to allow vehicles to pass. Thus, the B3 is not suitable for vehicle roadways or entrances requiring frequent vehicle passage. Instead, we developed the B3 for one or more of the following circumstances:

You want a barrier system that can be easily upgraded if security conditions change

You have a limited budget and require a perimeter security system that can be installed in phases over several budget cycles

Your perimeter security is more or less permanent, but you need occasional vehicle access (such as for construction, maintenance, or VIP vehicles)

CALL FOR A QUOTE TODAY 915-240-4747

![]()

Temporary Barriers which rest on the road surface are designed to be set up and removed quickly.

They can be set up at any location and are usually used for extra security at high-profile events or during a threat escalation. Types include:

Mobile barriers are self-contained trailers licensed for over-the-road travel, that can be pulled by a heavy-duty pickup truck. The barrier is moved into position across a roadway, the axle and wheels disengage, and the barrier is lowered onto the roadbed. These barriers can be operated manually, powered by an electrical umbilical, or powered from a self-contained electrical generator or solar array.

Portable barriers are essentially identical to mobile barriers, except they do not have wheels and are not configured as over-the-road trailers. They are typically trucked to their deployment site and then placed on the roadbed using a forklift or mobile crane. The model pictured above is a very low cost portable barrier that can be set up by one person in minutes and requires no heavy lifting equipment. It can be used as either a roadway barrier or a perimeter barrier.

Semi-Permanent barriers straddle the definition between permanent and temporary. They are delivered to the site and then anchored. Some types are built on large steel plates that bolt to the road surface. Others have massive housings on each end that are filled with concrete, sand, or other material. They are temporary in the sense they can be removed without major roadway excavation. However, they lack the major advantage of temporary barriers: rapid setup and takedown in response to changing security conditions.

![]()

Once positioned, the new Crash Barrier mobile barricade is separated from its transporter and lowered into position by means of a Battery-Operated Hydraulic Power System, which is then used to raise or lower the barrier for normal or emergency tasks.

The controls to run the barrier can be located on the barrier, at a fixed secure post, or from a hand-held push button controller.

The guard need not go to the barrier to raise or lower it from its guard position.

Within 15 minutes of being sited, the new MP-5000 Crash Barrier mobile crash barrier lowers itself into position with built-in hydraulic jacks.

There is no hand cranking.

![]()

![]()

Customs sizes and configurations are available.

![]()

Customs sizes and configurations are available

![]()

Customs sizes and configurations are available.

![]()

Customs sizes and configurations are available.

![]()

. Customs sizes and configurations are available

![]()

![]()

Where peace of Mind Begins

The surface mounted Traffic Controller IN 3 FOOT SECTIONS can quickly attach to existing driveways asphalt or cement.

No excavation or cutting is required in normal installations.

Any driveway can be controlled by installing unit's end to end.

Because the unit is above grade, drainage problems are minimal BUT SHOULD BE CONSIDERED

CALL FOR A QUOTE TODAY 915-240-4747

![]()

Cable Crash Beam barricades

Available in Hydraulic or Manually operated models.

All crash beams are rated as follows:

Navy tm-56-86-05: 1/l3.0 or 15,000 lbs @30mph 450,000 ft/lbs

or

k- 4 rating is 15,000 lbs @ 30 mph

k- 8 is 15,000 lbs @ 40 mph

k-12 is 15,000 lbs @ 50 mph

Enhanced Models are re-enforced for applications at High Security applications.

The clear

openings range from 10.5 to 20 feet (3200 mm to 7315 mm).

If You need a Barrier Longer than 20 feet Please call us

![]()

Model SP TT- 9218 Swing Arm Cable Beam Barricade

Swing Gate is manually operated.

Available with a Clear opening ranges from 10.5 to 24 feet.

Ideal for use at locations where vertical lift is impractical.

Model TT218M Manuel Or Hydraulic is configured as a swing gate for use where vertical lift is impractical

CALL FOR A QUOTE TODAY 915-240-4747

![]()

![]()

The Motorized Series directional traffic control systems are designed to provide vehicular directional lane control.

These systems are specifically engineered to act as a physical deterrent to wrong way traffic where directional lane safety or security is major concern.

The Motorized units are manufactured in standard three (3) foot increments, which allows for effective control of virtually any width traffic lane or drive way up to 30 feet

Each model is then field installed by bolting directly to the roadway in accordance with the number of units required,

Installation on a concrete surface is recommended however a two part epoxy can be used when installing on asphalt

The size of the hydraulic control unit is 12 wide x 36 Long x 30 Tall

Tunnel section is 36 long, the operating time to lower teeth is 1 second either way

Operates on a ½ hp 110 v sing phase 7 amp can be modified for 220 power

Available in Epoxy Urethane enamel Paint Yellow or Red

Comes pre-wired requiring only the connection to power and control circuits

, comes with documentation Mechanical Installation, electrical & control Installation, Start Up Procedures, Trouble Shooting Guide

Cost per Main Unit Which includes tunnel and 2 3 foot teeth panels is $8,750.00

Additional 3 foot panel with teeth are 975.00 each

Weight for hydraulic control cabinet 175 lbs and drive tunnel is 175 lbs

Control ramps weight 220 lbs each

CALL FOR A QUOTE TODAY 915-240-4747

![]()

Mega TOWER GATE OPERATOR

The MEGA-ARM barrier style parking gate operator is unique in the industry.

Setting the MEGA-ARM apart are many features that make it the front runner in its class. With standard features like: -

SENSES OBSTRUCTIONS GOING OPEN AND CLOSE

-RUST PROOF ALUMINUM lift arm or fiberglass

-MOLDED POLYETHYLENE UV COVER-optional

-BATTERY BACKUP

D MECHANISM

CALL FOR A QUOTE TODAY 915-240-4747

![]()

HTD 320 SERIES BARRIER GATE OPERATOR

The HTD 320 Series barrier gate operator comes in several versions and will handle arms up to 36 feet. This powerful hydraulic operator has all the standard features of other Hy-Security gate operators, including self-locking and soft start and stop for heavy arms and has no limits on daily duty cycles. Features sophisticated hydraulic design with no gearboxes, chains, sprockets, belts, clutches or rotary limits to maintain. Soft Stop is standard to reduce wear and prolong the life of the installation. All HTG Series operators are available with 24-VDC motors and uninterruptible power supplies. Anti-corrosion finish, electroplated, then coated with a high gloss powder paint finish. Inside mechanism diagram available. - 5 year warranty

HTG 320 SERIES BARRIER GATE OPERATOR SPECIFICATIONS:

![]()

![]()

When Your Serious About Security

![]()

CALL FOR A QUOTE TODAY 915-240-4747